Zogulitsa

API 7-1 Casing Section mphero chida

Mbiri ya malonda

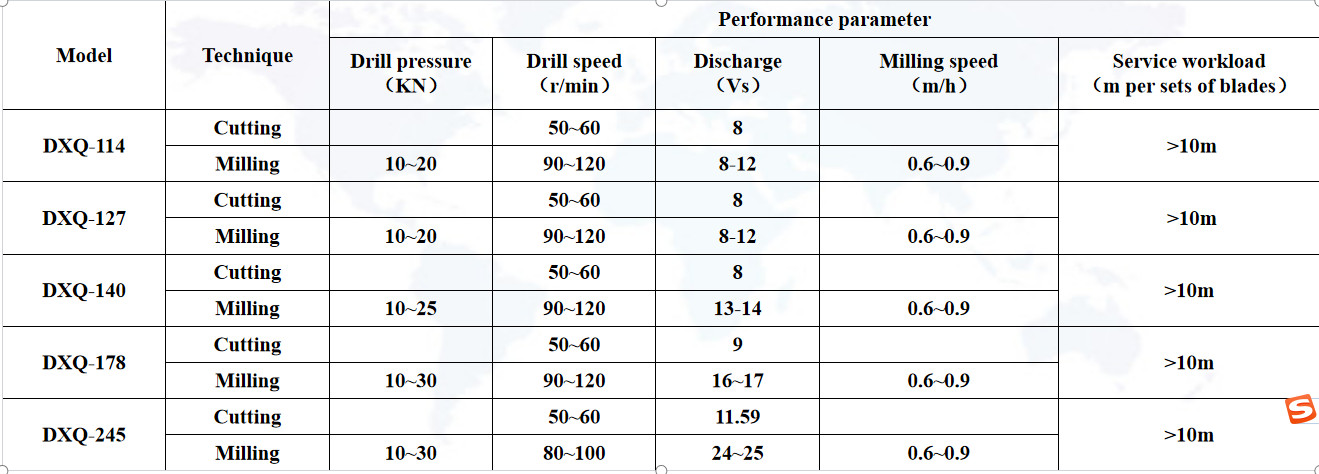

Gawo mphero ndi mtundu wa casing zenera kutsegula chida chomwe chimagwirizanitsa ntchito kudula casing ndi mphero.Chigayo chagawo chimalowera m'bokosi limodzi ndi BHA, ndikudula choyikapo pamalo osankhidwa poyamba.Pambuyo paketi yadulidwa kwathunthu, Idzadulidwa mwachindunji kuchokera pamalowa.Mukafika pakuya kwina, ntchito yotsegulira zenera la casing imamalizidwa.gawo mphero ali ndi ubwino dongosolo losavuta, ntchito yabwino kuti ikhale yothandiza kwambiri casing zenera kutsegula chida.

Panthawiyi, gawo mphero akhoza Finyani ndi jekeseni simenti ntchito bwino kusiyidwa, amene akhoza kupanga simenti mwachindunji kukhudzana ndi mapangidwe mtunda wautali mkati madigiri 360.Simentiyo imatha kulowa m'malo osungiramo zinthu molingana ndi porosity yomwe ilipo komanso ma fractures a mapangidwewo, ndipo plugging imakhala yabwino kwambiri kuposa kufinya simenti pambuyo pobowola.

Mfundo yogwira ntchito

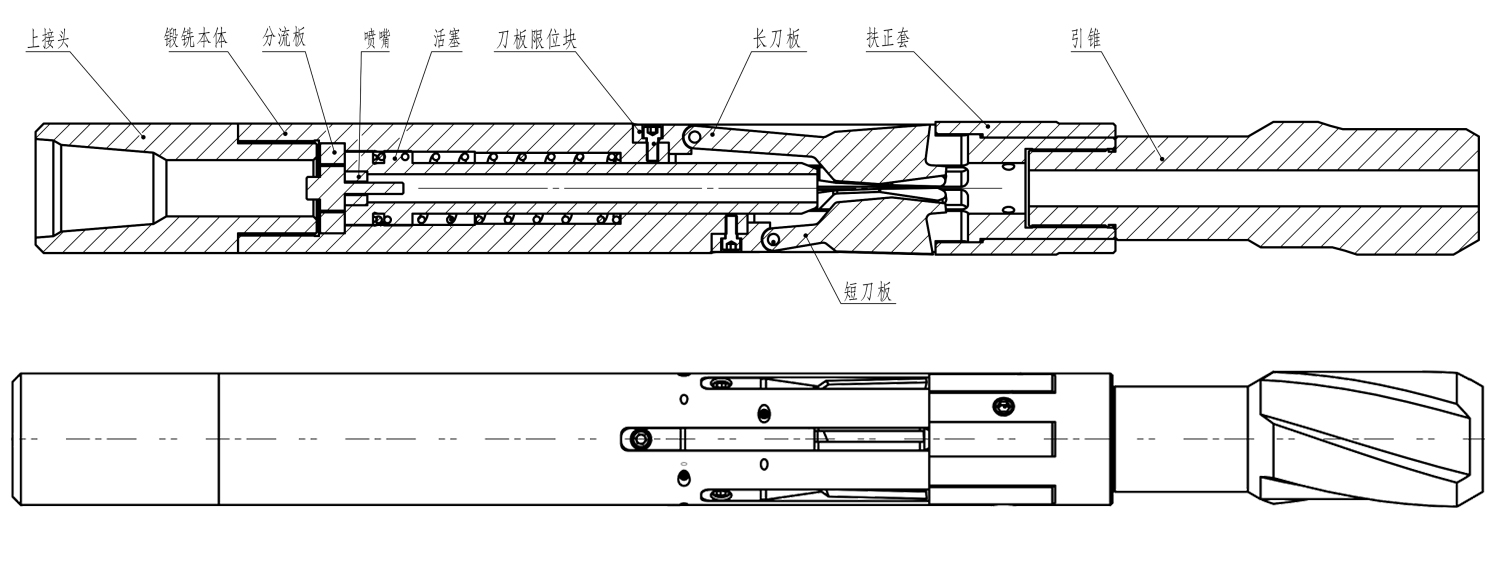

Pambuyo pa mpheroyo imatsitsidwa kumalo osankhidwa mu casing pamodzi ndi BHA, yambani tebulo lozungulira, kuyatsa mpope, pisitoni yomwe ili mu chida imakankhidwira pansi ndi kukakamizidwa, pisitoni yapansi ya pistoni imakankhira zitsulo zodula ndikutsegula. dzenje lotseguka.Pamene masamba odulidwa amatseguka mpaka kufika pamtunda waukulu, kukonza dzenje lotseguka kwatha.Pansi pa kuthamanga kwa mpope kosalekeza, tsambalo limatha kutsegulidwa ndikubwezeretsanso dzenjelo mwachindunji.Pampu ikayimitsidwa, pisitoni imayikidwanso pansi pa kasupe ndipo masamba odulira amangochotsedwa.

Zogulitsa

(1) Kupanga kwamakina, kapangidwe kosavuta komanso ntchito yosavuta

(2) Kuthamanga kwapansi koyambira ndi mphamvu yayikulu yothandizira masamba ndizothandiza podula casing;

(3) High mphamvu kasupe kapangidwe kumathandiza basi kubweza wodula pambuyo kudula;

(4) Mapangidwe a block block ndi pini ndiwothandiza kukakamiza kubweza chida;

(5) Tsambali lili ndi kukulitsa kwakukulu ndipo lingagwiritsidwe ntchito pakhoma lomwelo ndi makulidwe osiyanasiyana a khoma;

(6) Tsambalo limapangidwa ndi tungsten carbide yapamwamba kwambiri ndipo Bake hughes njira yowotcherera yofananira, yokhala ndi magwiridwe antchito apamwamba komanso moyo wautali wautumiki.

Gawo mphero-Kukula tebulo

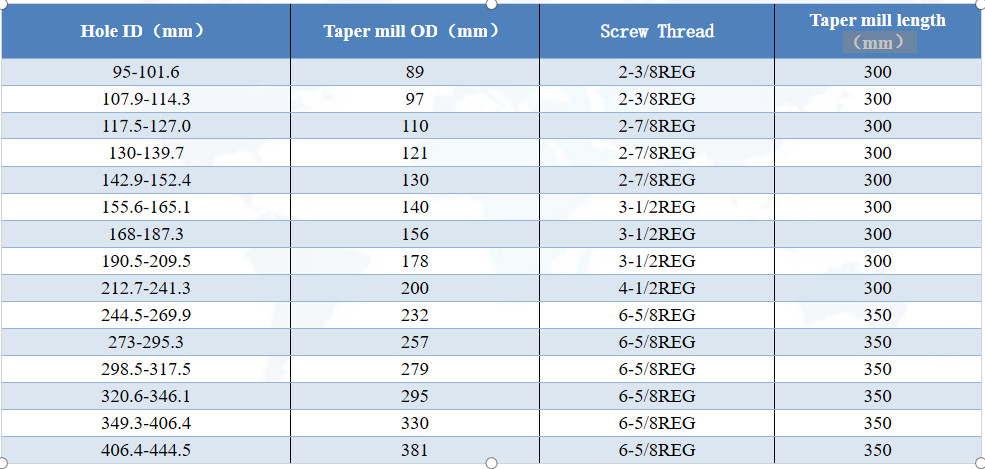

Zida zofananira - High class taper mill

Zida zogaya zonse zimapangidwa ndi aloyi apamwamba kwambiri a tungsten carbide ndi Baker Hughes ukadaulo womwewo wowotcherera.Cholinga cha mndandanda wa mphero ndi kubwezeretsa kwathunthu kusankha zinthu, kapangidwe kamangidwe ndi kuwotcherera ndondomeko ya Baker Hughes, kuti akwaniritse zomwezo mankhwala khalidwe la Baker Hughes.

2.High class wapampopi mphero mbiri

imatha kupanga mphero yapamwamba yokhala ndi mainchesi akunja a 76 mm mpaka 445 mm.Chitsulo cha alloy chapamwamba chimagwiritsidwa ntchito ngati thupi lalikulu, kulola kukonza mabowo akuluakulu amadzi kuti atsimikizire kutulutsa kosalala kwa zinyalala za mphero.Panthawi imodzimodziyo, malinga ndi zosowa zenizeni za makasitomala, kapangidwe kazinthu kakhoza kupangidwa kuti akwaniritse ntchito yabwino yogwiritsira ntchito.

3.Taper mphero-Kukula tebulo

Kapangidwe kazinthu

1. Gawo mphero makamaka limaphatikizapo zigawo zotsatirazi: cholumikizira chapamwamba, thupi lalikulu, pisitoni, nozzle, kudula masamba ndi chulu chowongolera, ndi zina zambiri.

III.Ubwino waukadaulo wa Petrozhr gawo mphero

1.Kupangidwa ndi tungsten carbide yapamwamba kwambiri

Magawo amphero opangidwa ndi kampani yathu ali ndi zabwino izi:

(1) Kuchita mphero ndi kudula kumathamanga kwambiri kuposa masamba wamba;

(2) Chepetsani kuthamanga kwa kubowola komwe kumafunikira kudula;

(3) Zolemba za mano ndizofanana ndipo palibe mtunda wopangidwa;

(4) Zinyalala zopangidwa ndi zofanana;

(5) Kuuma kwa zinthu zopangira ndikwapamwamba ndipo kapangidwe kake ndi koyenera.Akamagwira ntchito, ndi kudula zitsulo osati kugaya zitsulo.

2

Tungsten carbide yosankhidwa ndi kampani yathu idzatumizidwa ku bungwe loyesa akatswiri kuti likawunike gulu lililonse likafika.Kuonetsetsa kuti kuuma kwa aloyi ndi zizindikiro zina zimakwaniritsa zofunikira za kampani

3.Njira yabwino yowotcherera

Timagwiritsa ntchito wowotcherera wakale wa Baker Hughes ndikusankha zida zowotcherera zomwezo ndi zida zothandizira mu msonkhano wa Baker Hughes kuti tizindikire kupangidwanso kwaukadaulo wowotcherera wa Becker m'njira ndi zida.

Pofuna kuchepetsa mapindikidwe a zida chifukwa cha kusintha matenthedwe pamaso ndi pambuyo kuwotcherera, ife amakhazikitsa kuwotcherera kutchinjiriza dongosolo kuonetsetsa bata la mankhwala geometry ndi ntchito Mwachangu.

IV. Gawo mphero ntchito ndondomeko

Kukonzekera kwa Wellhole:

1. Konzani chotengera.Konzani posungira pansi ndi taper mphero kapena casing shaper.

2. Kuyeretsa Bwino.Tsukani mafuta osaphika kapena zakumwa zina m'chitsime ndi madzi aukhondo.

3. Kukwapula chotengera kapena chitsime.Kukwapula kwa chitoliro ndi kuyendetsa kumayenera kuchitidwa ndi scraper wamba ndi kutsetsereka m'mimba mwake mpaka 20 metres pansi pa gawo la mphero.

4. Konzani madzi amphero.Makhalidwe ake osiyanasiyana amatha kuonetsetsa kuti zinyalala zachitsulo zimakhala zokhazikika.

Mayeso apansi:

1. Yesani kudalirika kwa zida;

2. Kusintha kwa mphamvu ya mpope kumayesedwa pamene masamba odulidwa atsegulidwa, omwe amapereka maziko oweruza ngati chiwombankhanga chapansi chikudulidwa.

Kusankha malo ogaya:

1. Simenti kunja kwa gawo mphero casing ayenera bwino simenti.

2. Pewani malo omwe casing ili ndi kusuntha ndi kusinthika.Ngati pali malo oterowo, ntchitoyi iyenera kuchitidwa 30-40m pamwamba pa malo.

3. Thumba liyenera kusungidwa pansi pa shaft.Kawirikawiri, kutalika kwa thumba kuyenera kukhala kwakukulu kuposa 100m.

Kudula casing:

① Mukalumikiza chidacho mu BHA ndikuthamangira pagawo la mphero, yambitsani tebulo lozungulira kuti muwone malo olumikizirana ndi casing malinga ndi zolemba (zodula mitengo), ndikutsitsa chidacho mpaka pafupifupi 1-3m pamwamba pa kulumikizana ndi mabuleki apafupi. .

② Yambitsani tebulo lozungulira kaye, onjezani liwiro lozungulira mpaka 50-60r / min, yambani mpope, pang'onopang'ono onjezerani kusamuka, kuti pampu ionjezere.Panthawi imeneyi, kuthamanga kwa mpope kumawonjezeka kuchokera kuzing'ono kupita ku zazikulu, pang'onopang'ono kuwonjezeka mpaka 10-12mpa.

③ Pitirizani kudula casing kwa 20-45min.Pamene kuthamanga kwa mpope kumatsika mwadzidzidzi ndi 2-5mpa, casing imadulidwa.Pofuna kuti thupi lodulira litseguke bwino, sungani malo odulira pamalopo kwa 30min mutatha kudula, ndipo pang'onopang'ono muwonjezere kusamukako kuti muwonetsetse kuti fracture ipangidwe.

Milling casing:

WOB ikhoza kukulitsidwa pang'onopang'ono pambuyo podulidwa.yomwe imayendetsedwa pakati pa 10-25kn, kuthamanga kwa rotary kumawonjezeka kufika 80-120r / min, ndipo kuthamanga kwa pampu kumayendetsedwa mkati mwa 10MPa kuonetsetsa kuti kusuntha kozungulira kungathe kunyamula zinyalala zachitsulo.Gawo lirilonse likakhala pafupi ndi 0.5m, likhoza kubowoledwa 1m pa kukonzanso kamodzi ndi kuzungulira, kuti ziwongolere zinyalala zachitsulo zomwe zagayidwa kuchokera pagawolo kuti zibwerere bwino kudzera mu annulus.Pambuyo pa 1-2 kuzungulira kuzungulira, kubowolaninso kuti mupitilize kupanga ndi mphero.

[Pamenepo, m'pofunika kusintha bwino ntchito yamatope pamene mukuwonjezera kusamuka;nthawi yomweyo, sunthani chida chobowola moyenera ndikusintha mayendedwe kuti tchipisi tachitsulo tibwererenso ndikuteteza zinyalala kudzikundikira]

Room 703 Building B, Greenland center, Hi-tech Development zone Xi'an, China

Room 703 Building B, Greenland center, Hi-tech Development zone Xi'an, China 86-13609153141

86-13609153141